What is

Concrete Slab.

The concrete slab is a Horizontal structural element to provide a flat surface for arranging floors and ceilings . Concrete Slabs are reinforced with mild steel bars having

different diameters and surfaces like deformed steel bars and Twisted/Tor Bars

to produce good bonding with concretes.

Steel Types

used in Concrete.

According

to strength, there are two types of Steel used in construction.

1, Low

carbon Steel /Mild steel.

2, High

carbon steel.

In

construction Mild steel is usually used in all types of Civil engineering

structures but High carbon steel is preferred in Precast structures only.

Mild

steel or low carbon steel is mostly used

in construction because of its more protection against corrosion.

In

most structures Grade 60 is preferred because of economic suitability and its minimum Yield strength is

used in designing RCC structures.

|

STRENGTH in (PSI) |

Grade 40 |

Grade 60 |

Grade75 |

|

Minimum Yield Strength |

40000 |

60000 |

75000 |

|

Maximum Yield Strength |

60000 |

90000 |

100000 |

Concrete mix

for RCC/PCC slabs.

|

DETAILS

OF CONCRETES |

||

|

TYPE OF CONCRETE |

MIX RATIO |

COMPRESSIVE STRENGTH in (PSI) AFTER

28 DAYS |

|

PCC |

(1:5:10) |

1000 |

|

PCC |

(1:4:8) |

1500 |

|

PCC |

(1:3:6) |

2000 |

|

RCC |

(1:2:4) |

3000 |

|

RCC |

(1:1.5:3) |

4000 |

|

RCC |

(1:1:2) |

4500 |

Generally,

the above mixtures are used in the production of Plain cement concretes and

Reinforced cement concretes but special concretes may be produced by special

measuring and testing in labs. These special concretes are made for high

loading demands using moderated tools and materials and specialists are needed

to produce such high-strength concretes.

Some

of these special concretes are as follows

M25 (25MPa)= 3625 PSI

M30 (30MPa)= 3625 PSI

M35 (35MPa)= 5075 PSI

M40 (40MPa)= 5800 PSI

M50 (50MPa)= 6525 PSI

M55 (55MPa)= 7250 PSI

M60 (60MPa)= 8700 PSI

M65 (65MPa)= 9425 PSI

M70 (70MPa)= 10150 PSI

Methods of

Construction.

There are some methods involved in the Concreting process.

1- Preparation

of Flooring for Scaffolding.

Scaffolding

can be done on firm ground but there may be chances of settlement so it should

be better to lay Plain cement concrete which may be part of the floor in later

stages. Arrangement and fixing of scaffolding should be according to the weight

of Concrete which may be calculated from the following formula.

Weight

of plain cement concrete = Volume of concrete x Density of Concrete

Density

of Plain cement concrete=140 Pound/ Cft

Density

of Reinforced cement concrete=150 Pound/ Cft

One

scaffolding pipe can bear 2240 Pound Safely if braced at vertical interval or

3Ft.

So

the number of vertical pipes under PCC /RCC = Weight /2240= No of Pipes

Horizontal

pipes should be calculated according to the height of pipes and according to

loading of slabs.

2- Fixing of

Shuttering

It

is a very important stage as shuttering provides a firm platform for placing

concrete and steel, so shuttering should be water-tight so the cement paste may

not go out from the concrete mix as it will decrease the strength of cement

concrete. Shuttering may be made of wooden ply sheets supported by wooden beams, and may

also, be made of steel sheets supported by steel girders.

Shuttering

should be leveled as per drawing and design and also according to the elevation

of the building.

3- Fixing of Steel

Reinforcement.

Steel

reinforcement should be placed and fixed at shuttering platform according to

drawing and design of slab. There are different sizes of steel bars as

1.25" ,1" ,7/8",6/8",5/8",4/8"3/8"2/8"

used in building construction.In Oneway slabs Main bars are placed along short

spans whereas distribution bars are placed along the longer sides of slabs. In

TwoWay slabs both longer and shorter bars contribute equally so up or down does

not matter as per design aspects. Negative bars control negative moments that

apply on supports and up to the distance of L/4.Supporting bars should be

provided beneath the Negative bars usually at intervals of 12 " c/c.

Chairs should be provided to control the deflection of steel bars and to keep

steel in position during the concreting process.

Concrete

Spacers should be provided under the steel reinforcement mesh and also on the

sides of slabs, normally concrete cover is equal to the larger dia of steel

used in slab but the minimum cover should be up to 1/2".

4- Fixing of Electric and Plumbing Conduits.

After

steel electric and plumbing conduits should be placed as per the location of

electric fixtures like Fans, Lights, Fan Boxes Etc. Plumbing pipes are kept

vertically according to the required layout of lines. The position of lines

should not be disturbed during the concrete, Care should be taken to avoid the

breaking of pipes from the movement of labor and wheel borrows because broken

pipes get choked and hinder the passage of electric cables in later stages

which causes problems of rerouting by doing more wall trenching and fixing and

inserting new cabling.

5- Mixing and

Placing of Concrete.

Concrete

maybe mixed by hand or in the mechanical mixer, it should be methodically

mixed and the concrete placed in its final position with the minimum delay.

Normal RCC Works are constructed using (1:2:4) mix with concrete incidents as

Cement, Sand, Crush, Water, Steel Reinforcement, and Admixtures. Three mixing

practices can be adopted for concreting 1, By Hand Mixing, 2, By Machine Mixing

3, By Batching Plant.

The most prominent mixing method is mixing by batching plant as quantities can be

measured with controlled mechanism but such mixings are only required to avail

high strength concretes which requires more than 4000 PSI compressive strength.

Batching plants prepare the concrete using weights of ingredients that are

mentioned in the job mix formula. Transportation of concrete Transit mixer

trucks is used whose minimum volume may be 5 cum. In Some places, the batching

plants are available at the construction site and concrete is transported to

the workplace using tower cranes and pumps along with pipelines.

Batching

plants are used for massive construction projects and for normal works such a the method is not affordable at all.

Mixing

by hand may be adopted for small works in which all ingredients are mixed

roughly for two minutes on cleaned and water-tight platforms. An additional

quantity of cement up to 10 % should be added in such mixes to ensure the

quality of concrete.

In

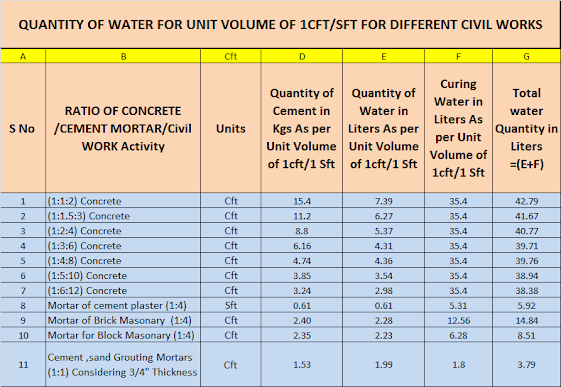

any case, water should be added only according to suitably designed Water

Cement Ratios because excessive water reduces the strength of concrete.

On

the Construction of slabs for small houses, mixture machines are used along

with a tower lift to transporting the concrete on the heights OF slabs, if the

quantity of concrete is massive than more than one machine and tower lifts can

be fixed to avoid delays in the pouring of slabs.

Compaction

of concrete is very important as it provides dense concrete expelling the air

voids from the concrete volume and also increases the strength of concretes.

Compacting

can be efficiently done using Vibrator machines, the vibration should be 1 minute

for 1 cum of concrete, Over vibration should be avoided as it segregates the

ingredients of concrete.

Concrete

should be smooth and well leveled using wooden and steel floats, Level points

may be maintained by the surveyor to ensure the exact thickness of the slab on

all portions.

6- Curing of Concrete slabs.

Curing is an important activity as this saves concrete from hydration which causes cracks and strength losses in concrete structures so curing should be executed at least for 14 days for slab structures because in 14 days concrete maintains 90 % of its ultimate strength.

7-Removing of shuttering and scaffolding.

Removing

of shuttering may be started after 14 days for medium spans of the building but

larger spans should not be suspended before 28 days as concrete avails its 100

% strength in 28-days.